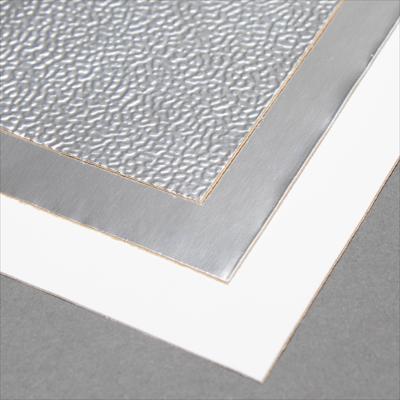

JA-0777 | HVAC Tape | jacketing | aluminium foil | acrylic adhesive

Item No. WEB0075

JA-777 is an insulation jacket for interior and exterior HVAC ducts, piping and equipment. Top performance features: used on mechanical (glassboard or polyurethane) Insulation (HVAC Insulation) constitutes a Flexible Non-permeable Water and Vapor barrier antimicrobial treatment for Fungi Resistance

Description

JA-777 is an insulation jacket for interior and exterior HVAC ducts, piping and equipment.

Top performance features:

Top performance features:

- used on mechanical (glassboard or polyurethane) Insulation (HVAC Insulation)

- constitutes a Flexible Non-permeable Water and Vapor barrier

- antimicrobial treatment for Fungi Resistance to inhibit mold growth

- multifunctional self-adhesive cladding product made with a multi-layer aluminum foil laminate. Generally used to provide a total vapor barrier and complete moisture protection through jacketing applications. It is considered a heavy duty patch and repair tape for use on large diameter piping systems in industrial plants. This product can also be used as a strapping tape for the installation of subsea pipe-in-pipe insulation. Ideal Seal 777 is a performance system that delivers savings in time, labor, and costs. The unique design offers easy installation and repositioning.

- grey

- white

- 895MMx46M

Specifications

- -- PROPERTIES --

- ----------

- Application

- JACKETING

- Product

- 0777

- Color

- SILVER

- Total thickness (micron)

- 74

- Backing material

- ALUMINIUM FOIL

- Adhesive system

- ACRYLIC ADHESIVE

- -- PERFORMANCE --

- ----------

- Elongation (%) (Afera 5004)

- 270

- Peel adhesion 90° (N/25MM) (Afera 5001)

- 16N/25MM

- Peel adhesion 180° (N/25MM) (Afera 5001)

- 12.7N/25MM

- Dwell time (hrs)

- 72

- Peel multiplier @ dwell time (%)

- 155

- Tack level (ASTM D3121)

- ROLLING BALL 7CM

Storage conditions

Pressure sensitive tapes need to be stored under defined conditions. Extreme high temperatures can lead to degradation of the adhesive or backing materials. Extreme low temperatures might influence the bonding characteristics.

The generally recommended storage conditions are:

The bonding surface should be clean and dry, free from any contaminants that may affect the adhesive bond, such as dust, grease, oil or lint.

This stage can involve the use of evaporative solvents such as methyl ethyl ketone (MEK) to remove compounds accumulated through prior use or exposure to the elements and/or cleaning products such as isopropyl alcohol, esters, and naphtha-based products.

Some projects may require primer application, flame treatment, corona treatments or pretreatment methods to improve surface energy.

Unwinding

Dispense the tape. JA-0777 comes with the unique Ideal dispenser box that prevents rolling, fly aways and wasted material. Easy to control, carry and store.

Application – act

Sometimes clean removal of pressure sensitive tape can be difficult without damaging the substrate that it is adhered to. Pulling at a slow rate and with a low angle of peel helps reduce surface damage. PSA residue can be softened with certain organic solvents or heat.

Discard / Recycle

This is a temporary tape – once removed one can discard / dispose without special instructions.

ABI Tape takes responsibility for our planet. As such, we are currently working on tapes that have an accelerated biodegradable function on the backing. Stay tuned …

Pressure sensitive tapes need to be stored under defined conditions. Extreme high temperatures can lead to degradation of the adhesive or backing materials. Extreme low temperatures might influence the bonding characteristics.

The generally recommended storage conditions are:

- 68 - 72 F / 20 - 22 C

- 50 - 70% relative humidity

- Rolls store flat in their original packaging, away from direct sources of UV (i.e., lights, sun).

The bonding surface should be clean and dry, free from any contaminants that may affect the adhesive bond, such as dust, grease, oil or lint.

This stage can involve the use of evaporative solvents such as methyl ethyl ketone (MEK) to remove compounds accumulated through prior use or exposure to the elements and/or cleaning products such as isopropyl alcohol, esters, and naphtha-based products.

Some projects may require primer application, flame treatment, corona treatments or pretreatment methods to improve surface energy.

Unwinding

Dispense the tape. JA-0777 comes with the unique Ideal dispenser box that prevents rolling, fly aways and wasted material. Easy to control, carry and store.

Application – act

- The product should be applied to the ducts sides in the following order: bottom, sides and top.

- All sections of the product should overlap by at least 7,5 cm.

- All seams should face towards the bottom of the duct.

Sometimes clean removal of pressure sensitive tape can be difficult without damaging the substrate that it is adhered to. Pulling at a slow rate and with a low angle of peel helps reduce surface damage. PSA residue can be softened with certain organic solvents or heat.

Discard / Recycle

This is a temporary tape – once removed one can discard / dispose without special instructions.

ABI Tape takes responsibility for our planet. As such, we are currently working on tapes that have an accelerated biodegradable function on the backing. Stay tuned …

Questions? Get in touch with our product specialist directly!

Robrecht Van Vaerenbergh | Business Unit Manager | Technical, HVAC & double sided products

phone +32 55 23 51 58 | mobile +32 472 22 41 76 | mail robrecht.vanvaerenbergh@abitape.eu

Robrecht Van Vaerenbergh | Business Unit Manager | Technical, HVAC & double sided products

phone +32 55 23 51 58 | mobile +32 472 22 41 76 | mail robrecht.vanvaerenbergh@abitape.eu

CONTACT US

JA-0777 | HVAC Tape | jacketing | aluminium foil | acrylic adhesive

Item No. WEB0075

JA-777 is an insulation jacket for interior and exterior HVAC ducts, piping and equipment. Top performance features: used on mechanical (glassboard or polyurethane) Insulation (HVAC Insulation) constitutes a Flexible Non-permeable Water and Vapor barrier antimicrobial treatment for Fungi Resistance

Description

JA-777 is an insulation jacket for interior and exterior HVAC ducts, piping and equipment.

Top performance features:

Top performance features:

- used on mechanical (glassboard or polyurethane) Insulation (HVAC Insulation)

- constitutes a Flexible Non-permeable Water and Vapor barrier

- antimicrobial treatment for Fungi Resistance to inhibit mold growth

- multifunctional self-adhesive cladding product made with a multi-layer aluminum foil laminate. Generally used to provide a total vapor barrier and complete moisture protection through jacketing applications. It is considered a heavy duty patch and repair tape for use on large diameter piping systems in industrial plants. This product can also be used as a strapping tape for the installation of subsea pipe-in-pipe insulation. Ideal Seal 777 is a performance system that delivers savings in time, labor, and costs. The unique design offers easy installation and repositioning.

- grey

- white

- 895MMx46M

Specifications

- -- PROPERTIES --

- ----------

- Application

- JACKETING

- Product

- 0777

- Color

- SILVER

- Total thickness (micron)

- 74

- Backing material

- ALUMINIUM FOIL

- Adhesive system

- ACRYLIC ADHESIVE

- -- PERFORMANCE --

- ----------

- Elongation (%) (Afera 5004)

- 270

- Peel adhesion 90° (N/25MM) (Afera 5001)

- 16N/25MM

- Peel adhesion 180° (N/25MM) (Afera 5001)

- 12.7N/25MM

- Dwell time (hrs)

- 72

- Peel multiplier @ dwell time (%)

- 155

- Tack level (ASTM D3121)

- ROLLING BALL 7CM

Storage conditions

Pressure sensitive tapes need to be stored under defined conditions. Extreme high temperatures can lead to degradation of the adhesive or backing materials. Extreme low temperatures might influence the bonding characteristics.

The generally recommended storage conditions are:

The bonding surface should be clean and dry, free from any contaminants that may affect the adhesive bond, such as dust, grease, oil or lint.

This stage can involve the use of evaporative solvents such as methyl ethyl ketone (MEK) to remove compounds accumulated through prior use or exposure to the elements and/or cleaning products such as isopropyl alcohol, esters, and naphtha-based products.

Some projects may require primer application, flame treatment, corona treatments or pretreatment methods to improve surface energy.

Unwinding

Dispense the tape. JA-0777 comes with the unique Ideal dispenser box that prevents rolling, fly aways and wasted material. Easy to control, carry and store.

Application – act

Sometimes clean removal of pressure sensitive tape can be difficult without damaging the substrate that it is adhered to. Pulling at a slow rate and with a low angle of peel helps reduce surface damage. PSA residue can be softened with certain organic solvents or heat.

Discard / Recycle

This is a temporary tape – once removed one can discard / dispose without special instructions.

ABI Tape takes responsibility for our planet. As such, we are currently working on tapes that have an accelerated biodegradable function on the backing. Stay tuned …

Pressure sensitive tapes need to be stored under defined conditions. Extreme high temperatures can lead to degradation of the adhesive or backing materials. Extreme low temperatures might influence the bonding characteristics.

The generally recommended storage conditions are:

- 68 - 72 F / 20 - 22 C

- 50 - 70% relative humidity

- Rolls store flat in their original packaging, away from direct sources of UV (i.e., lights, sun).

The bonding surface should be clean and dry, free from any contaminants that may affect the adhesive bond, such as dust, grease, oil or lint.

This stage can involve the use of evaporative solvents such as methyl ethyl ketone (MEK) to remove compounds accumulated through prior use or exposure to the elements and/or cleaning products such as isopropyl alcohol, esters, and naphtha-based products.

Some projects may require primer application, flame treatment, corona treatments or pretreatment methods to improve surface energy.

Unwinding

Dispense the tape. JA-0777 comes with the unique Ideal dispenser box that prevents rolling, fly aways and wasted material. Easy to control, carry and store.

Application – act

- The product should be applied to the ducts sides in the following order: bottom, sides and top.

- All sections of the product should overlap by at least 7,5 cm.

- All seams should face towards the bottom of the duct.

Sometimes clean removal of pressure sensitive tape can be difficult without damaging the substrate that it is adhered to. Pulling at a slow rate and with a low angle of peel helps reduce surface damage. PSA residue can be softened with certain organic solvents or heat.

Discard / Recycle

This is a temporary tape – once removed one can discard / dispose without special instructions.

ABI Tape takes responsibility for our planet. As such, we are currently working on tapes that have an accelerated biodegradable function on the backing. Stay tuned …

Questions? Get in touch with our product specialist directly!

Robrecht Van Vaerenbergh | Business Unit Manager | Technical, HVAC & double sided products

phone +32 55 23 51 58 | mobile +32 472 22 41 76 | mail robrecht.vanvaerenbergh@abitape.eu

Robrecht Van Vaerenbergh | Business Unit Manager | Technical, HVAC & double sided products

phone +32 55 23 51 58 | mobile +32 472 22 41 76 | mail robrecht.vanvaerenbergh@abitape.eu

CONTACT US

العربية (مصر)

العربية (مصر)